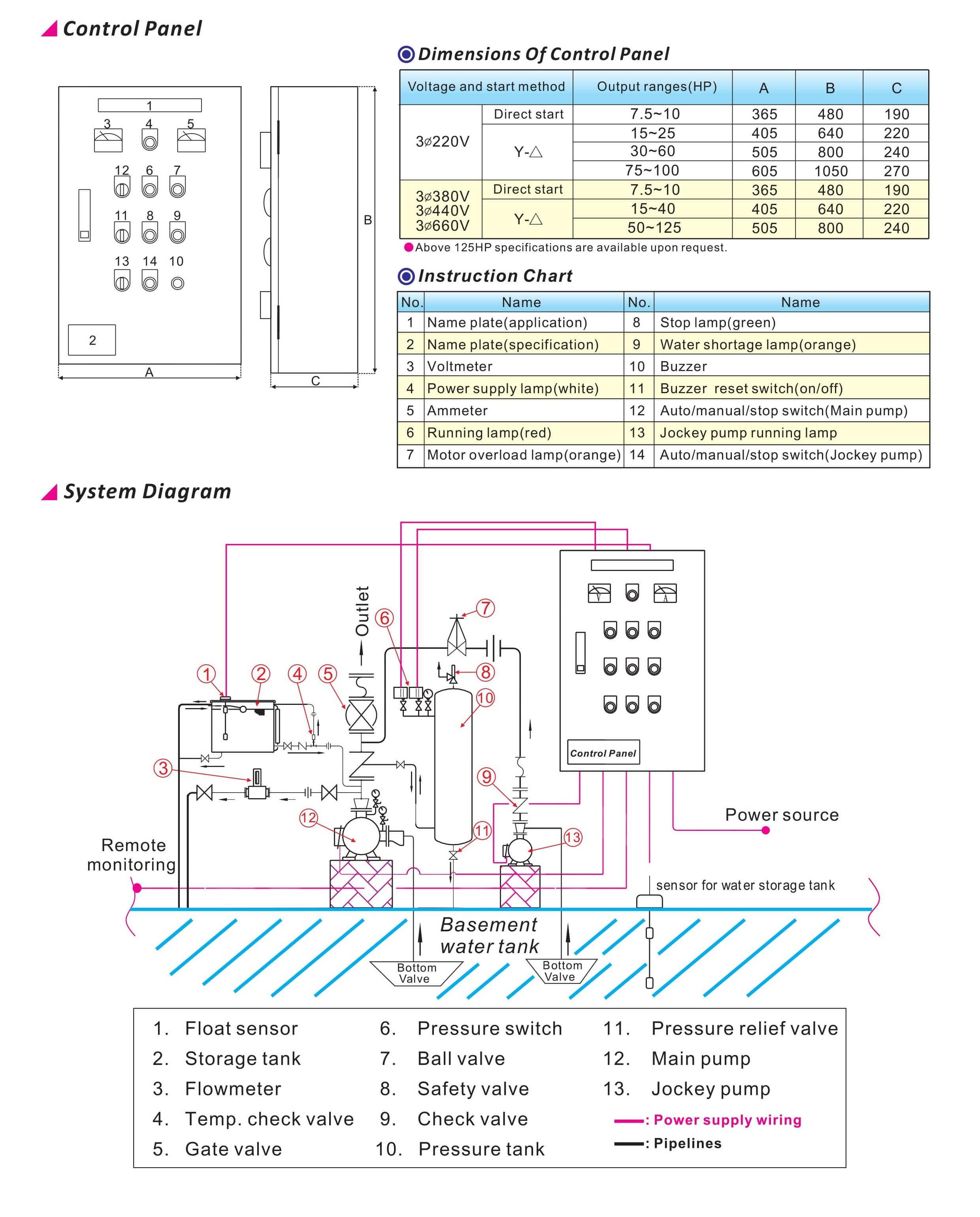

Function: In order to avoid frequent running of main pump due to minor water leakage or small water volume required, the mounting of jockey pump is purposed to take care of the water leakage or small water volume in this regard, that is, jockey pump will be started/ stopped when there is an occurrence of water leakage taken place to the pipeline while the main pump will not be started.

Water supply and auto boost water pressure to the fire sprinkler system, fire hydrant, fire foam system of the buildings, malls, hotels, factories, stadium, parking area, stations, airports, schools, etc.

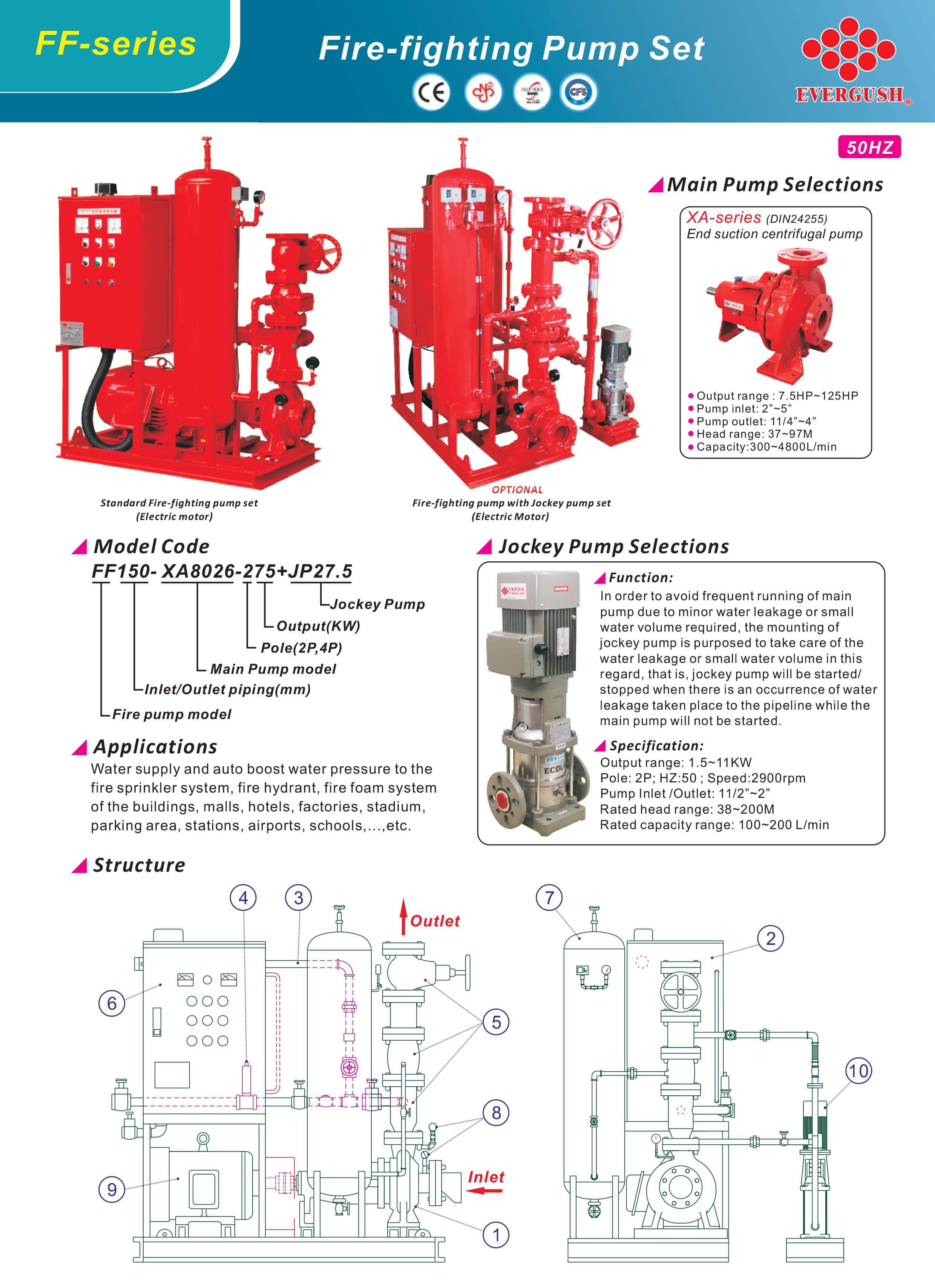

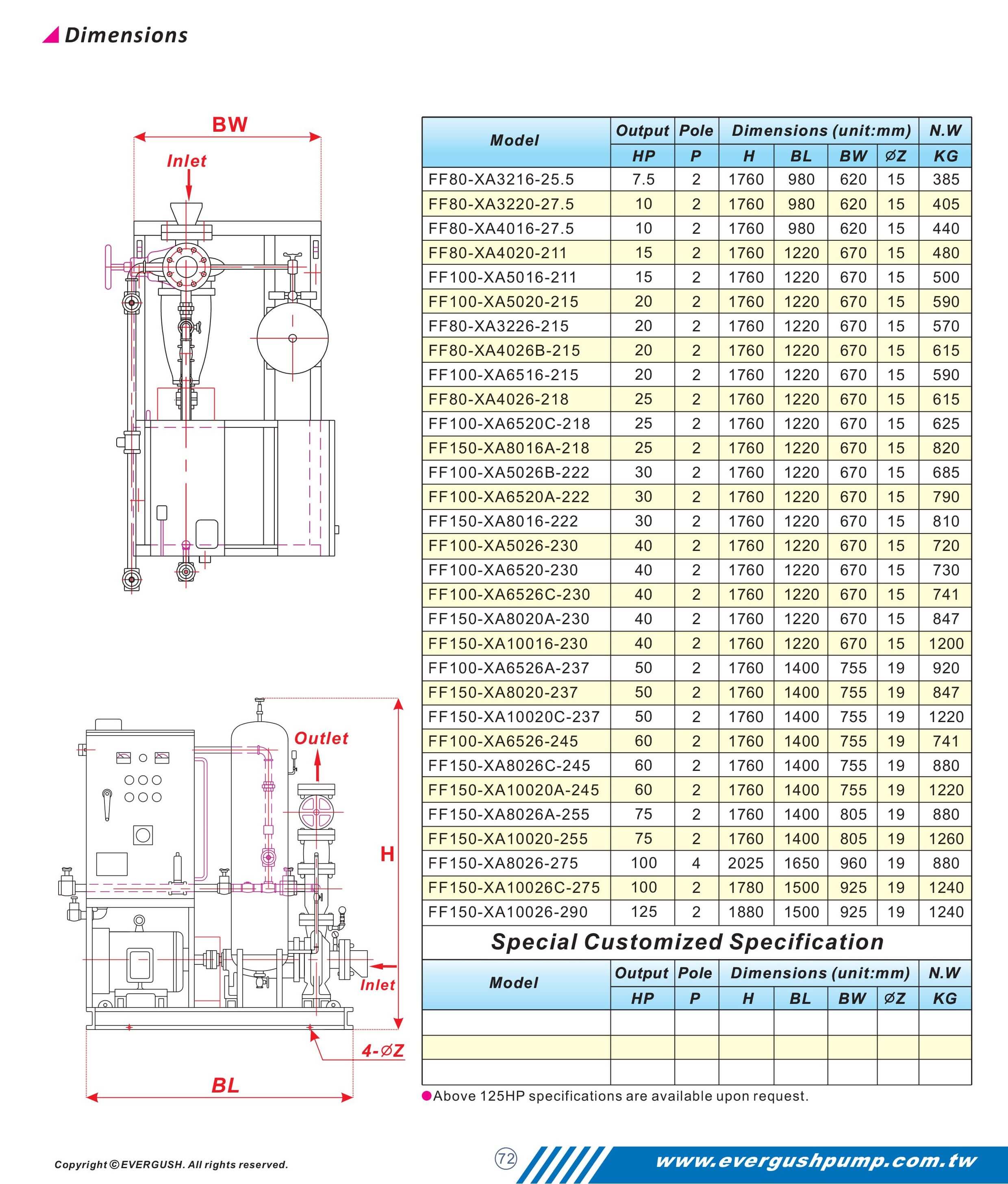

Adopting XA model End suction single stage centrifugal pump

1.1 In accordance with DIN24255(EN733) standard.

1.2 Back-pull-out design for easily repairing.

1.3 Shaft sealing with mechanical seal.

1.4. diverse material options of pump casing, shaft, and impeller.

1.5. 42 different sizes in the range.

1.6. Capacity:1080M3/hr.

1.7. Head up to 100meters.

1.8. Operating pressure: Max.1.0~1.6 Mpa.

2.1 Outfit: Water storage tank for priming water, drain pipes for overflowing water, water-stopping cock with removal of remaining water, makeup water inlet connector(floating ball valve included), alarm device for low water level, auto water makeup device(check valve and water-stop clock included).

2.2 Storage tank is made of steel plate while its capacity of effective storage volume is above 100L.

2.3 Piping diameter of water supply pipes: 15A, drain pipes for water overflowing: 50A, water priming pipe: 40A.

2.4 Alarm device for low water level: Applied the floating ball switch or the electrode method; the alarm will be triggered when the water level in water storage tank has been dropped to ½ capacity.

3.1 The discharging pipe for preventing the temperature rise of water is connected to the primary side of check valve to the discharging side of water pump with an orifice plate mounted in between them so that the pump can discharge minor volume of water into the room-temperature water storage tank during its operation.

3.2 There shall be no valves with a diameter bigger than 15A mounted to the piping of discharging pipes for preventing the temperature rises of water.

3.3 The water volume flowing inside the discharging pipe for preventing the temperature rise of water is able to prevent the water temperature inside the water pump from going higher than 30OC when pump is at fully-shut status and continuous running condition.

4.1 Able to test the pump water capacity during regular check.

4.2 Flow way flowmeter to measure and read directly the rated water volume and the range of 150% rated flow.

4.3 Mounted a pressure gauge with a precision above 1.5 class.

5.1 If required Head is over 100M: ductile Iron silent check valve, ductile Iron Gate valve, Other connecting piping,20K flanges.

5.2 If required Head is below 100M: cast Iron silent check valve, cast Iron gate valve, other connecting piping,10K flanges.

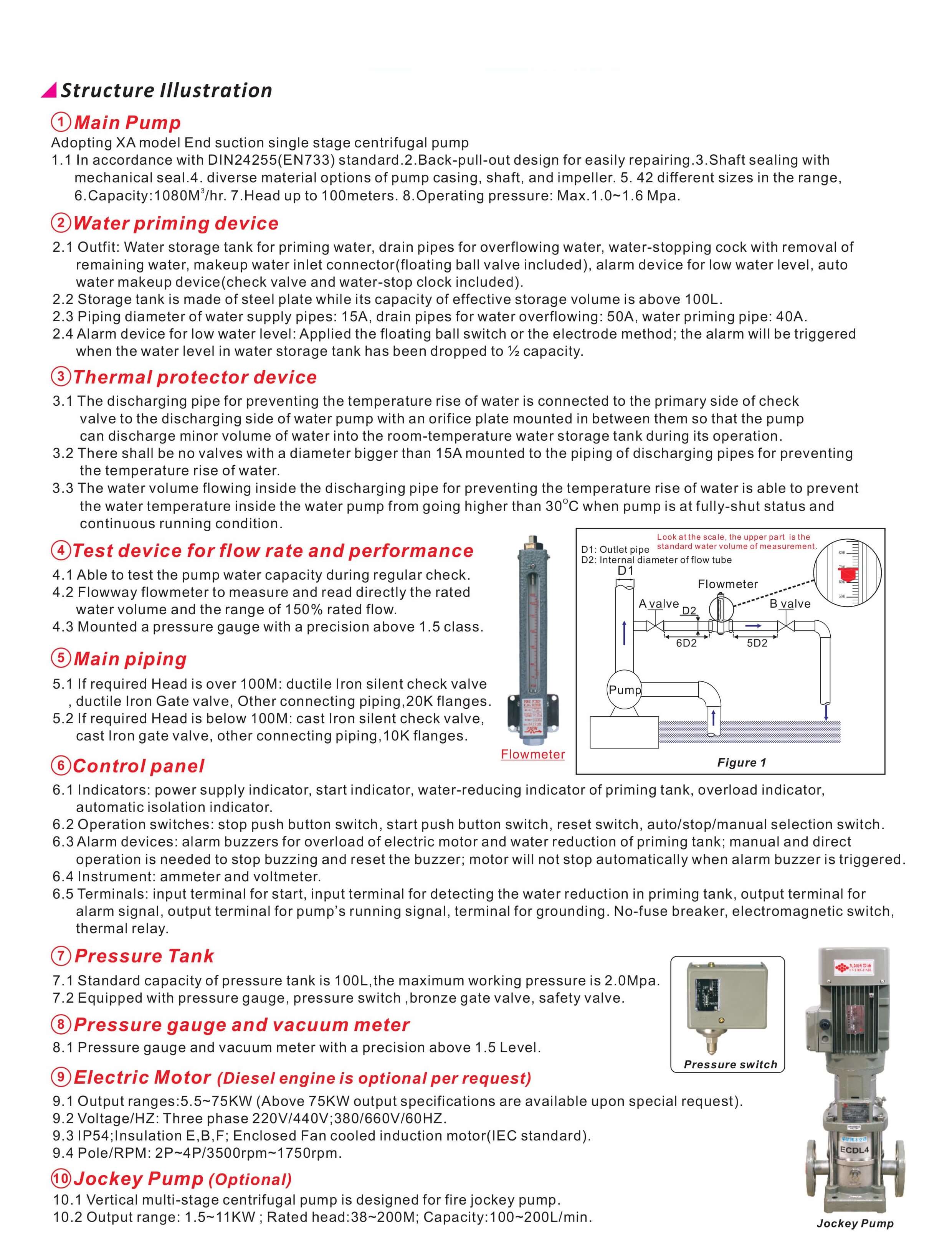

6.1 Indicators: power supply indicator, start indicator, water-reducing indicator of priming tank, overload indicator, automatic isolation indicator.

6.2 Operation switches: stop push button switch, start push button switch, reset switch, auto/stop/manual selection switch.

6.3 Alarm devices: alarm buzzers for overload of electric motor and water reduction of priming tank; manual and direct operation is needed to stop buzzing and reset the buzzer; motor will not stop automatically when alarm buzzer is triggered.

6.4 Instrument: ammeter and voltmeter.

6.5 Terminals: input terminal for start, input terminal for detecting the water reduction in priming tank, output terminal for alarm signal, output terminal for pump’s running signal, terminal for grounding. No-fuse breaker, electromagnetic switch, thermal relay.

7.1 Standard capacity of pressure tank is 100L, the maximum working pressure is 2.0Mpa.

7.2 Equipped with pressure gauge, pressure switch, bronze gate valve, safety valve.

8.1 Pressure gauge and vacuum meter with a precision above 1.5 Level.

9.1 Output ranges:5.5~75KW (Above 75KW output specifications are available upon special request).

9.2 Voltage/HZ: Three phase 220V/440V;380/660V/60HZ.

9.3 IP54;Insulation E,B,F; Enclosed Fan cooled induction motor(IEC standard).

9.4 Pole/RPM: 2P~4P/3500rpm~1750rpm.

10.1 Vertical multi-stage centrifugal pump is designed for fire jockey pump.

10.2 Output range: 1.5~11KW ; Rated head:38~200M; Capacity:100~200L/min.

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.